|

Brush Electrical Machines is a manufacturer of large generators for gas turbine and steam turbine drive applications, based at Loughborough in Leicestershire, United Kingdom. In 1879, a company was established in Lambeth London, called the Anglo-American Brush Electric Light Corporation. Its formation was to exploit the invention of Charles Francis Brush, who was born in Cleveland Ohio in 1849 and who had invented his first electric dynamo in 1876. He founded a company called the American Brush Company, which stayed in business in the USA until about 1891. As the business grew in Lambeth due to the demand for new electrical apparatus, larger premises were required and the Anglo-American Brush Electric Light Corporation moved 100 miles north to the Falcon Works at Loughborough in 1889. Over the next sixty years the business grew by acquisitions until in 1957 the Brush companies were incorporated into the Hawker Siddeley Group under the new name of the Brush Electrical Engineering Company Limited. Within the Hawker Siddeley Group the company manufactured a vast range of electrical products including; turbo-generators, salient pole machines, induction motors, traction motors and generators, traction locomotives, switchgear, transformers and fuses. In November 1991 Hawker Siddeley Electric Power Group was subject to a hostile takeover bid of £1.5 billion from BTR plc, the large engineering conglomerate. The bid was successful so the Brush companies then became part of the BTR organisation. The most recent change in Brush’s history occurred in November 1996 when the FKI Group of Companies acquired the Hawker Siddeley Electric Power Group from BTR for a price of £182 million. On 1 July 2008, Melrose plc completed the acquisition with FKI, Melrose being a specialist investor in the manufacturing industry, is now registered on the London Stock Exchange. During the last 125 years various Brush companies (Brush Switchgear, Brush Transformers, Brush Traction and Brush Control Gear) have existed on the Falcon Works site, but throughout this period Brush Electrical Machines Ltd manufacturing generators and motors has always been the largest company. Over 5,000 staff were employed on the site during the 1960s and 70s; today there are approximately 720 staff, 450 of which are direct production personnel. The following products are manufactured at the Loughborough facility: Air-cooled turbogenerator in the range of 20 to 225MVA, Turbomotors from 10 to 100MW and the associated control equipment each

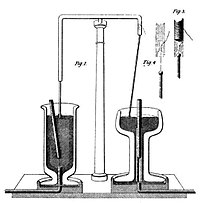

Brush Electrical Machines works in Loughborough, United Kingdom. Electrical engineering is a field of engineering that generally deals with the study and application of electricity, electronics and electromagnetism. The field first became an identifiable occupation in the late nineteenth century after commercialization of the electric telegraph and electrical power supply. It now covers a range of subtopics including power, electronics, control systems, signal processing and telecommunications. Electrical engineering may include electronic engineering. Where a distinction is made, usually outside of the United States, electrical engineering is considered to deal with the problems associated with large-scale electrical systems such as power transmission and motor control, whereas electronic engineering deals with the study of small-scale electronic systems including computers and integrated circuits. Alternatively, electrical engineers are usually concerned with using electricity to transmit energy, while electronic engineers are concerned with using electricity to process information. More recently, the distinction has become blurred by the growth of power electronics An electric motor converts electrical energy into mechanical energy. Most electric motors operate through interacting magnetic fields and current-carrying conductors to generate force, although a few use electrostatic forces. The reverse process, producing electrical energy from mechanical energy, is accomplished by some type of generator such as an alternator or a dynamo. Many types of electric motors can be run as generators, and vice versa. For example a starter/generator for a gas turbine, or traction motors used on vehicles, often perform both tasks. Electric motors are found in applications as diverse as industrial fans, blowers and pumps, machine tools, household appliances, power tools, and disk drives. They may be powered by direct current (e.g., a battery powered portable device or motor vehicle), or by alternating current from a central electrical distribution grid. The smallest motors may be found in electric wristwatches. Medium-size motors of highly standardized dimensions and characteristics provide convenient mechanical power for industrial uses. The very largest electric motors are used for propulsion of large ships, and for such purposes as pipeline compressors, with ratings in the millions of watts. Electric motors may be classified by the source of electric power, by their internal construction, by their application, or by the type of motion they give. The physical principle of production of mechanical force by the interactions of an electric current and a magnetic field was known as early as 1821. Electric motors of increasing efficiency were constructed throughout the 19th century, but commercial exploitation of electric motors on a large scale required efficient electrical generators and electrical distribution networks. The conversion of electrical energy into mechanical energy by a electromagnetic means was demonstrated by the British scientist Michael Faraday in 1821. A free-hanging wire was dipped into a pool of mercury, on which a permanent magnet was placed. When a current was passed through the wire, the wire rotated around the magnet, showing that the current gave rise to a close circular magnetic field around the wire. This motor is often demonstrated in school physics classes, but brine (salt water) is sometimes used in place of the toxic mercury. This is the simplest form of a class of devices called homopolar motors. A later refinement is the Barlow’s wheel. These were demonstration devices only, unsuited to practical applications due to their primitive construction.

Jedlik’s "electromagnetic self-rotor", 1827. (Museum of Applied Arts, Budapest. The historic motor still works perfectly today.)

From Wikipedia, the free encyclopedia : Manufacture of electric motors, generators, transformers and switchgear and controlgear |